FACTORIES TOURS

Joan Bonastre, S.A. is a long family tradition company that offers high-quality and precise bar-turning for those companies or projects that require a supplier to provide them added value, and through our engineering department, satisfy and perfect their most complex products.

Our vocation for high-level projects has led us to become a reference partner within high-demanding sectors such as the biomedical.

Teknia Barcelona, located in Parets del Valles (Barcelona) forms part of the TEKNIAGROUP machining business unit. This business unit also has plants in Mexico DF and Bilbao (Spain). The core business is bar turning in CNC single and Multi-spindle lathes, along with grinding facilities (Centerless & Plongee) Teknia Barcelona sells to a customer base entirely made up of Automotive companies, of which 85% is exported.

To achieve this there is a workforce of over 140 who are highly trained and partake in continuous improvement programs.

The company began its journey in the late sixties as a fusion of local machining workshops. In 1998 considerable growth culminating in the centralization of activity in a green field project (1200m²) in Parets del Valles under the name Talleres DEIS S.A. This new location entirely focused on machining – bar turning, facilitated notable growth in output and quality which in turn allowed expansion on an International scale.

In 1992 DEIS S.A. was incorporated into the Teknia Manufacturing Group and renamed TEKNIA DEIS with the aim of promoting growth and professionalism.In 2008 the trading name was changed again to TEKNIA Barcelona after the incorporation of two business units made up of locally acquired machining companies. From here on there has been an important change in technology along with the integration of LEAN philosophy.

Terrats Medical S.L. was founded in 1947 in Barcelona. It started as a manufacturer of precision mechanical component and, over the years, has become a reference company in the manufacture of medical and dental components.

At Terrats Medical we rely 100% of our production on Swiss and Japanese CNC machinery since 1994. Today we have a wide range of sliding head turning machines that increase every year thanks to our permanent growing production.

AVINENT is a complete partner of oral solutions. The quality of its product portfolio is based on scientific research and technological innovation, which have been the pillars of the continuous development of the company for 60 years.

This dedication to always offering high-quality products and services has led us to the world forefront of customized solutions.

We provide clinics, laboratories and hospitals with customized digital solutions and full digital workflow technology they need to offer high-quality treatments.

Our main commitment is to improve the well-being of people with less invasive treatments, faster and more precise, totally personalized and careful with the aesthetic result.

Our team of professionals provide solutions with high added value and complete support for dental clinics (AVINENT Implant System and AVINENT Orthodontics), prosthetic laboratories (AVINENT CadCam) and maxillofacial surgeons (AVINENT CMF).

Decolletatge Farrés, S.A. “DECFA” is a familly company established in 1973 and driven by the second generation.

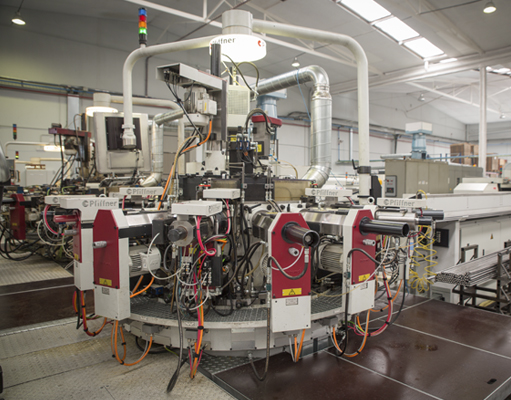

Our beginnings come from the motorbike industry and turned on to the automotive and industrial applications industries nowadays. We are mainly focused on the middle and large serial production using both cam machines and CNC Multi and Single Spindle Lathe Machines and Transfert Rotary Machines.

Also a large machinery park of arificial vision machines helps us to achieve most demanding goals. As a customer-service focused company, the automation of all our process and the formation of our staff are the basis of our development.

Vilardell Purtí is positioned in the market for the machining of parts produced in decolleting of great technical complexity and high added value.

Great production capacity in different sections of machinery, first-line level of technology, which provides very high precision parts, with an excellent level of finishes and meeting the strictest requirements and regulations in the international arena. Our target industrial sectors are automotive, aeronautics and in general all electro-mechanical components.

The basic operation of our production process is the decolleting of precision parts in mechanical and CNC mono-axis (moving head) and with mechanical and CNC multi-axis.

In addition, we have machinery for complementary processes of decolleting which give us the possibility of delivering products to our customers with very advanced phases, including the assembly and control of complex sub-assemblies.